How the Southeast Is Embracing Sustainable Neighborhood Design

- Value Added

- Our Products

- Residential - Interior

- Residential - Exterior

- Commercial

- Specialty Commercial

- Branches

- Design Options

- PAY NOW

- Exporting

- Multi-Family

- Vendors

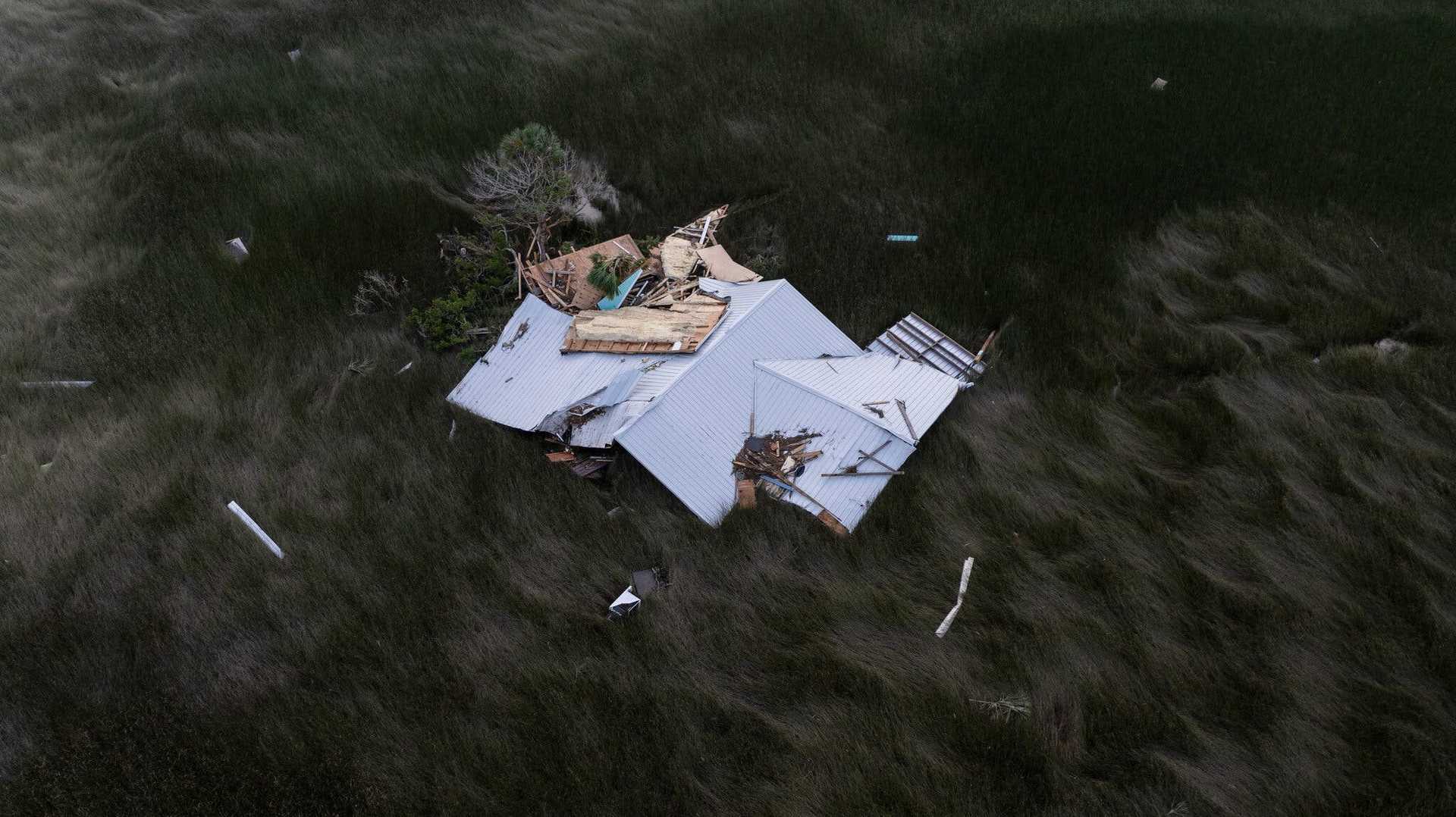

In the aftermath of Hurricane Helene, homeowners and builders are seeking more durable and wind-resistant roof systems. The FORTIFIED building program is designed to increase the structural integrity of homes, providing weather-resistant roofing materials that protect against wind, rain, and hail. This program was developed by the IBHS (Insurance Institute for Business and Home Safety) who create and conduct tests for building practices to decrease property damage. IBHS recommends constructing a FORTIFIED Roof with ZIP System by Huber Engineered Woods. This system simplifies FORTIFIED requirements and creates a sealed roof deck assembly to prevent water intrusion.

The FORTIFIED Home program consists of three levels: Roof, Silver, and Gold. Roofs are often the first line of defense under severe weather conditions. The reinforced FORTIFIED Roof equips a structure to handle high winds and heavy rain. Without these reinforcements, wind can lift shingles, and water can leak through the roof deck, causing significant damage to the interior of a home. The following are requirements for a FORTIFIED Roof: A FORTIFIED Roof requires the following:

The last line of defense on a roof is the roof deck. Leakage between panel seams is the primary cause of water intrusion during storms. A sealed roof deck creates a continuous weatherproof barrier. In contrast, an unsealed roof deck can allow up to 60% of rain to enter the attic.

A FORTIFIED Roof assembly is contingent upon the following:

ZIP System by Huber Engineered Woods reduces the material and installation time necessary to meet FORTIFIED Roof requirements. The ZIP System combines engineered wood products with an integrated weather-resistant barrier and acrylic tape. A sealed roof deck assembly utilizing the ZIP System prevents up to 95% of water from entering the attic and eliminates the need for additional felt and self-adhering membrane layers.

Tests conducted by the IBHS exposed the ZIP System to conditions equivalent to Hurricane Caroline, which included 105 mph winds and 2,000 gallons of rain in just 30 minutes. Despite these extreme conditions, the ZIP System maintained a dry attic, demonstrating its effectiveness as a stormproof roofing solution.

Insurance companies and government-funded grant programs recognize the value of FORTIFIED building practices. For example, select Alabama insurance companies offer premium discounts of up to 35% for a FORTIFIED Roof, 45% for Silver, and 55% for Gold certification. Up to $10,000 in grants are available to homeowners looking to make hurricane-resistant roof upgrades, and some insurance policyholders may qualify for a $3,000 deduction.

In Florida, insurance companies in select counties offer discounts for damage-reducing building practices, and the Florida PACE program offers financing to assist with hurricane preventative upgrades. Programs prioritizing the FORTIFIED method also exist in Mississippi, the Carolinas, and Oklahoma. Other states with incentive programs include Connecticut, Louisiana, Maryland, New Jersey, New York, Rhode Island, and Texas. For more details, visit the FORTIFIED building program website here.

With FORTIFIED building practices, suppliers confidently offer reliable products, builders use weather-resistant roofing systems, and homeowners feel safer when disaster strikes. The ZIP System by Huber Engineered Woods is a key player in constructing a FORTIFIED Roof and has proven its ability to withstand severe weather conditions.

Visit the FORTIFIED website to learn more about their program here.

Looking to incorporate Huber’s ZIP System into your next build? Contact participating Dixie Plywood locations in Atlanta, Dallas, Fort Lauderdale, Houston, Orlando, San Antonio and Tampa.