How the Southeast Is Embracing Sustainable Neighborhood Design

- Value Added

- Our Products

- Residential - Interior

- Residential - Exterior

- Commercial

- Specialty Commercial

- Branches

- Design Options

- PAY NOW

- Exporting

- Multi-Family

- Vendors

Why UFP Edge Thermally Modified Cladding Is the Perfect Choice for Sustainable Projects.

Thermally modified wood is redefining sustainable building with innovative products like UFP Edge Thermally Modified Cladding. This eco-friendly alternative offers enhanced performance, durability, and versatility, making it an ideal choice for contractors, homeowners, and retailers. Moreover, it provides an affordable alternative to traditional wood, which is often less sustainable. Although early attempts at thermal modification date back to the Vikings, this time-tested technique is now gaining traction in the U.S. market. In this blog, we’ll explore what makes thermally modified wood unique, its many benefits, and why UFP Edge stands out for your next project.

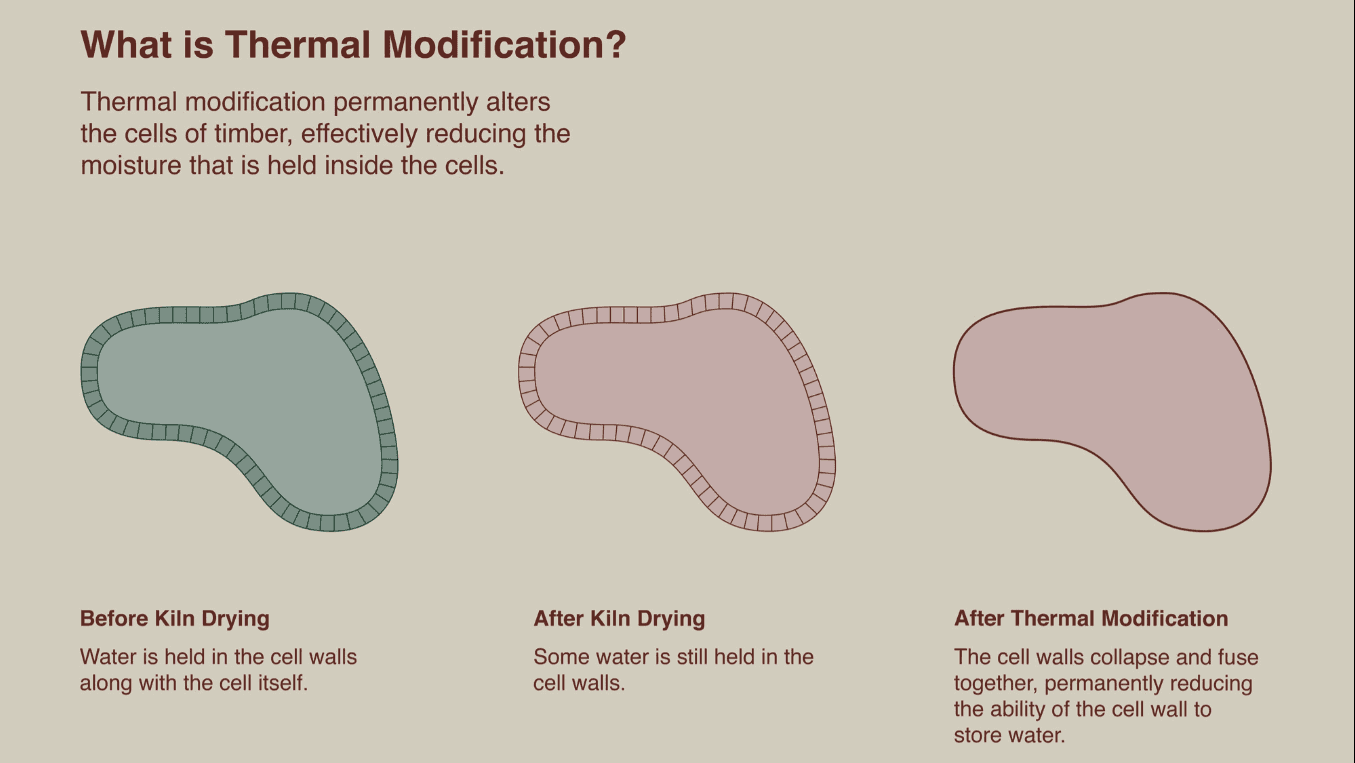

Thermally modified wood undergoes a three-phase process that combines heat, steam, and an oxygen-deprived environment to transform its chemical composition. Ideal for both interior and exterior applications, this treatment enhances durability, stability, and resistance to decay.

How It Works:

- Raw wood is placed in a thermokiln and exposed to temperatures ranging from 356–446°F.

- The moisture content is reduced to 0%, and hemicellulose (the component responsible for water absorption) breaks down.

- The wood is reconditioned to stabilize at a moisture content of 4–7%, ensuring dimensional stability.

The Result: The wood becomes hydrophobic (water-resistant), durable, and resistant to mold, rot, and insects. It also achieves a rich, exotic appearance, similar to tropical hardwoods.

Thermally modified wood offers unparalleled advantages over untreated, pressure-treated, and composite lumber alternatives:

- Durability: Achieves a Class 1 durability rating, with resistance to rot and decay for up to 20 years.

- Dimensional Stability: Minimal cupping, warping, or swelling, even in high humidity or extreme temperatures.

- Weight Reduction: The 60% reduction in moisture content results in a lighter board.

- Aesthetics: A consistent chocolate-brown color throughout the wood provides a luxurious, natural look.

- Eco-Friendliness: No chemicals are used—just heat and steam—resulting in a sustainable product with a net-negative CO2 profile.

- Versatility: Ideal for decking, siding, cladding, and interior finishes, with superior heat and sound insulation.

- Low Maintenance: Requires occasional cleaning and a UV-resistant sealer to maintain its rich color.

PRO TIP: While thermally modified wood is highly durable, the process reduces its natural bending strength by approximately 10%, making it unsuitable for structural applications.

UFP Edge Thermally Modified Cladding combines the benefits of thermal modification with modern design and sustainability, offering a superior product for residential and commercial projects.

Species: Pine and Vertical Grain Hemlock.

Profiles: T&G Nickel Gap, Bevel, and T&G V-Groove.

Finish: Wire-brushed for a premium texture, available in natural and color finishes.

Sustainability: Sourced and manufactured in North America.

Warranty: A 20-year transferable warranty against rot and decay ensures long-term reliability.

Source: https://www.ufpedge.com/-/media/project/ufpi/edge/general-literature/ufpedge-product-guide.pdf?dmc=1&ts=20241210t2038357713&sc_lang=en

Pressure-Treated Wood: Unlike pressure treated, thermally modified wood is more dimensionally stable and visually appealing, without the use of chemicals.

Composites: TMW offers sustainable, natural alternatives while composites are manufactured with synthetic additives.

Ipe and Teak: Thermally modified wood is significantly easier to source, more eco-friendly, and requires less maintenance.

For best results, follow these guidelines when installing UFP Edge Thermally Modified Cladding:

Preparation:

- Acclimate boards for 72 hours before installation.

- Record moisture content to ensure uniformity.

- Use a moisture-resistant barrier on structures.

Installation:

- Avoid ground contact and areas with frequent water exposure.

- Install over a rainscreen with a ½" gap and furring strips 24" OC.

- Use stainless steel fasteners to prevent corrosion.

- To review the full installation guide, click here.

Finishing:

- Seal all exposed edges and cut ends with a UV-resistant clear coat.

- For natural finishes, apply water or oil-based coatings to maintain the brown hue. Untreated wood will weather to a silver-grey.

- For color finishes, reapply every 7–10 years for optimal appearance.

- Clean regularly with a pressure washer to maintain the warranty.

To review the full UFP Edge catalogue, click here.

PRO TIP: When sourcing UFP Edge, purchase your entire job plus an additional 10% for consistency.

Source: https://www.ufpedge.com/products/siding/tmw-vg-hemlock

As sustainability continues to shape modern construction practices, thermally modified wood is rapidly emerging as a reliable and eco-friendly solution. According to market research, the thermally modified wood sector is expected to grow by 9.5% annually over the next five years. Furthermore, North America is projected to lead this growth, driven by increasing demand for sustainable materials.

With its combination of innovation, durability, and sustainability, UFP Edge Thermally Modified Cladding stands out as the ideal choice for builders, architects, and homeowners alike. Whether you’re designing a residential project or a large-scale commercial build, this product offers a high-performance solution that meets the evolving needs of today’s market.

When you are ready to integrate UFP Edge into your next project, contact our Dixie Plywood distribution centers in Fort Lauderdale, Orlando, and Tampa for more information, or visit UFP Edge’s website.